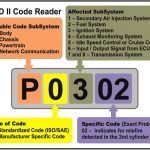

When your car shows a Check Engine Light (CHECK ENGINE LIGHT), you can find out what the cause is by deciphering the codes. The codes are made up of letters and numbers, with the first three being single digits from 0 to 3 and the fourth and fifth digits together. The fourth and fifth digits are pairs of numbers from 00 to 99. When these codes appear on your dashboard, you should take action as soon as possible.

P0128

The P0128 check engine fault code is associated with a problem with the engine’s coolant system. It indicates that the engine coolant is not getting warm enough and it’s not achieving its proper operating temperature. This error can affect both fuel economy and emissions. While the cause is usually a malfunctioning thermostat, other problems with this component can also cause this error code. Here are some possible solutions to this issue.

First, you’ll want to check the temperature of your engine. While this code won’t actually cause your car to shut down, it may not be as simple as a sticking thermostat. This issue can lead to the temperature gauge not reaching its ideal levels and could damage your engine. To prevent such a situation, you should take your car to a mechanic for a diagnosis. Fortunately, it’s a relatively easy fix and the cost is very low.

The most common cause of this error code is a faulty engine coolant thermostat. The radiator hose is an excellent diagnostic tool. Make sure the hose is still barely warm before the thermostat opens. When it does open, hot coolant should flow through it. If it doesn’t, then you should look at another component or check the coolant thermostat itself. If you can’t locate the issue, you’ll need to consult a mechanic or a car service center.

The most obvious solution is to find a mechanic who specializes in this repair. Although there are many Chilton repair manuals on the market, a subscription to ALLDATA is the best way to save money. A subscription to ALLDATA will allow you to get comprehensive factory repair information for one car or multiple. In addition, a DIY-friendly way to fix a P0128 code is to find a mechanic who can work with you at home.

If your vehicle is emitting P0128 check engine fault codes, the problem is likely to be a coolant thermostat. This could cause serious engine damage. In addition to fuel economy issues, coolant temperature problems can affect emissions. If left unchecked, these problems can lead to serious engine damage. When your car displays a P0128 error code, it’s important to diagnose the problem immediately, since a faulty thermostat can lead to the problem and the engine’s performance will be significantly compromised.

DPFE sensor

A DPFE sensor is a small rectangular component that is typically located behind the upper intake manifold, near the EGR valve. It has two vacuum hoses at the bottom and a wire harness coming out of the side. The location of your sensor will vary slightly depending on your make and model. If your car is displaying any of these trouble codes, you will need a repair manual. Alternatively, you can find your vehicle’s manual and refer to the diagram for the DPFE sensor.

If you see that your DPFE sensor is causing trouble, you should first check the condition of your vehicle’s EGR system. Whether the EGR valve is open or closed, it should change its RPM accordingly. However, if it isn’t opening, it may be due to a faulty vacuum seal. In this case, you can either replace the valve or the DPFE sensor. Replacing the DPFE sensor will likely solve the problem.

A faulty DPFE sensor is another common cause of check engine fault codes. It can affect the EGR system, which is critical for EPA fuel economy. Faulty DPFE sensors can affect the EGR system, resulting in poor performance and rough idle. If your car is experiencing any of these symptoms, you should have it checked by a mechanic. These diagnostics will give you the information you need to make the proper decision for your vehicle.

If your DPFE sensor is malfunctioning, your car’s idle quality will significantly drop. To ensure optimum performance, you must increase the engine speed to 2 500 rpm. The vacuum level must be adjusted to 8.5 or 9 in-hg, which is typical. The signal voltage from your DPFE sensor should be 4.9 to 5 volts. If your vehicle displays a voltage of less than 4.9 volts, it is almost certainly a defective sensor.

If you’re looking to repair your car’s DPFE sensor, it may be a good idea to refer to a Haynes manual. This manual includes step-by-step procedures, system descriptions, and maintenance schedules. Often, a faulty DPFE sensor will be the culprit behind your vehicle’s check engine fault codes. If you can’t find one of these manuals in your car’s Haynes repair manual, we recommend a Haynes auto repair guide.

EGR valve position sensor

If your EGR valve position sensor isn’t giving you 100% reading, it’s time to replace it. If you’re experiencing stalling, loss of power, or other symptoms, the sensor could be defective. To replace this sensor, first unplug the connector. Next, check for resistance, continuity, and signal ground. Finally, inspect the EGR valve for any blockage or other elements. If it’s damaged or worn, it needs to be replaced.

A malfunctioning EGR valve position sensor can also cause an illuminated malfunction indicator light to illuminate on the dashboard. It can also affect drivability, as the EGR signal is crucial for the engine management system. An improper signal from the EGR valve can result in engine knocking or elevated emissions that can cause detonation. The best way to fix an EGR valve position sensor is to purchase a scan tool and use it to check the position and pressure of the exhaust gas hose.

A scan tool that monitors EGR valve position can also detect additional codes that help diagnose the problem. For instance, you can use a speedometer cable to check the EGR valve for any carbon buildup. You may also want to clean the throttle body to get rid of any carbon buildup. Once you’ve performed the diagnostics, you’re ready to repair the EGR valve position sensor. If you can’t replace the EGR valve, you’ll need to replace the wiring.

An EGR valve position sensor failure can also result in check engine fault codes. This code can occur due to a number of factors, such as an improperly calibrated ECM or a defective fuel injector. However, it’s important to remember that a failed diagnostic is no cause for alarm. Instead, the problem could be something as simple as a malfunctioning EGR valve position sensor. The diagnostic can be done by following the manufacturer’s instructions.

In the case of intermittent failure, it may be necessary to perform a manual test. Observing the EGR valve’s position with a scanner can help determine whether the problem is related to the EGR valve. A malfunctioning EGR valve could be the result of carbon buildup or moisture freezing. In the meantime, you should check the condition of the vacuum supply hose. If the vacuum is not present at the “open” position, then you may have a faulty vacuum switch or solenoid.

Crankshaft position sensor

One of the most common OBD2 trouble codes is P0335, which indicates the crankshaft position sensor is failing. The sensor measures the position of the crankshaft and relays that information to the PCM. The P0335 code will turn on your Check Engine Light, indicating that the engine is in trouble. Here are some common causes and symptoms. When you notice the code, take action immediately.

If the resistance reading from the PCM connector is not okay, or the fault occurs intermittently, you need to replace the crank sensor. This procedure may also resolve a PCM fault. The codes P0335 and P0385 refer to the crankshaft position sensor “A” and “B,” respectively. Other crank sensor codes are P0016, P0017, and P0018. If none of these codes apply, then the sensor may not be faulty.

The sensor is an electronic component that monitors the crankshaft’s position and speed. Sometimes it is referred to as the engine speed sensor. It is made to withstand extreme heat and other forces that are put on the engine. A bad sensor will not send any signal to the car’s computer, and a mechanic may have to replace the crankshaft. If your car has a bad crankshaft position sensor, you should replace it with an OEM quality part.

Failure of the CMP sensor can be dangerous. In some cases, the sensor is intermittent or complete. A complete failure can be dangerous, requiring you to watch for a car approaching at 70 miles per hour or worse. Alternatively, you may notice that the engine won’t start. Either way, you need to get it checked as soon as possible. That way, you can avoid any accidents. If you don’t want to risk a collision, you should replace the sensor as soon as possible.

While a damaged crankshaft position sensor can cause the check engine light to turn on, there are other issues that can set off the light. Your car may stall at a certain point, showing a problem with the camshaft or the motor. It may also run rough or stall if you try to rev it up. This can be a sign of a more serious problem that will require a repair.