The rising number of turbocharged vehicles in the market should translate to new sales potential for aftermarket workshops.

Although the service life of a turbocharger should be identical to that of the engine, certain circumstances like poor maintenance, inadequate lubrication or excessive exhaust gas will require premature replacement. A turbocharger is designed to match the service life of the engine. However, the high-tech components in the exhaust gas system are exposed to risk factors which could lead to their failure, such as foreign bodies penetrating the turbine, dirty oil, faulty oil supply or excessively high exhaust gas temperatures. Technicians need know-how to cope with these issues.

Design and function of turbochargers

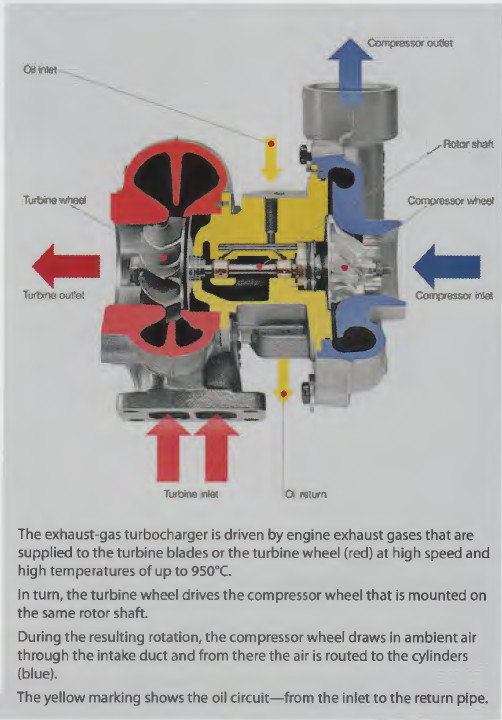

The power output of an internal combustion engine mainly depends on the air mass supplied to the combustion process and this can be increased by employing a turbocharger .

It uses exhaust gas energy to precompress the intake air and supply a greater air mass, and therefore more oxygen to the engine, achieving greater efficiency in the combustion process.

Exhaust gas turbocharging allows an increase in maximum torque and maximum power output while retaining constant work volume, and a rise in mean pressure without requiring any mechanical drive output from the engine that normally occurs with mechanical supercharging such as from a compressor . This increase can be harnessed to fit a more powerful engine with approximately the same dimensions as the original engine. Alternatively – and the trend is pointing in this direction – it can be used to implement downsizing concepts that can lower fuel consumption and C02 emissions without a tradeoff on power output.

Analysis is important

A precondition for a successful repair is that the cause of the failure must be identified and eliminated, otherwise there is a risk that the new turbocharger will fail again after a short time.

Cleanliness is indispensable

Even the smallest of foreign bodies acts like a projectile at the enormously high speeds of the turbine and compressor wheels.

The air filter has to be replaced in every case. Just as important is the careful cleaning of the entire intake and fresh air system to and from the charge air cooler, including the removal of all foreign bodies from the exhaust pipe.

Lubrication is a must:

The rotor shaft bearing needs engine oil.

Pour a little engine oil into the oil inlet bore before installing a new turbocharger (pic 1). Place a clean cloth over this (pic 2) and then distribute the oil in the bearings with a short blast from a compressed air gun (pic 3).

After installing the turbocharger and before connecting the oil supply, pour some more engine oil into the oil inlet bore. A small syringe with engine oil is enclosed with the MAHLE turbocharger sets of seals to make this work easier.

The turbocharger needs engine oil for lubrication and cooling and this is supplied by the oil pump in the engine. The oil is returned to the circuit via the oil return pipe.

The complete oil return pipe and connection to the crankcase must be laid without any kinks and must be free from deposits so that the oil is transported smoothly. If the return flow is disturbed this can lead to blockages and the turbocharger will lose oil through the turbine and compressor wheels. Major engine damage could be the consequence . A new oil return pipe is just as sensible an investment as a new charge air cooler.

There should be no excess pressure in the crankcase.

If the crankcase vent is dirty an excess pressure builds up that hinders the return flow of oil in the turbocharger.

The turbocharger starts to lose oil through the turbine and compressor wheels as soon as an excess pressure of only a few millibars is measured at the dipstick tube. All connections on the turbocharger must be tight so that oil, air, exhaust gases and, depending on the type, cooling water can be passed through the turbocharger cleanly, safely and without losses. Each MAHLE turbocharger has a matching mounting kit consisting of seals as well as exactly fitting built-on parts.

Only ever use these original sets of gaskets and never use the old gaskets again. They are often deformed or porous and cannot guarantee the necessary seal.

Sealing compound or liquid sealers are also forbidden on the turbocharger. Sealing compound may reduce the cross-section of the bores and parts of the sealing compound may become loose and block the supply of oil. The consequence could be major damage to the turbocharger .

The oil supply and return lines often run very close to the turbocharger. Car manufacturers protect the oil pipes with shielding. Check that this is still in place and undamaged.

A new turbocharger should always be given new oil and a new oil filter. This ensures that any foreign bodies in the oil system are eliminated and cannot damage the new turbocharger. After all, the old turbocharger failed and this may have been due to infiltrated foreign bodies.

‘If a little is good, more is better’ does not hold true for the oil level. If the oil level in the engine is too high it can lead to disturbances of the compression ratio in the engine. This forces engine oil into the turbine and compressor of the turbocharger where it collects in the charge air cooler. If this oil is sucked in and burnt again by the engine, major engine damage could follow.

Once the turbocharger has been fitted, the oil and possibly the water lines connected, and the air and exhaust gas lines connected to the turbocharger, the oil can be changed and the cooling system vented.

Ignition must be prevented when the engine is started. This is done by removing the fuel pump’s fuse or relay.

Turn the engine with the starter until oil pressure has been built up.

If the engine is being started for the first time it is recommended that the engine is left idling for two minutes before opening the throttle to ensure the supply of oil.

Next check that all screws and connections are tight and that there are no leaks. This check should be done again after running for about 20 hours or 1,000 km.

A turbocharged engine takes poorly to short trips because after a cold start the unburnt fuel and condensation water collects in the engine oil.

This worsens the tribological properties (friction, lubrication and wear) of the oil and reduces the carrying capacity of the lube oil film.

These unwanted companions only disappear at oil temperatures above 80°C.

If the oil temperature stays below this level for a longer period of time, as is the case with short trips, this constitutes a risk for the turbocharger.

The bearings of the crankshaft and camshaft and rotor shaft in the turbocharger become worn.

At low outside temperatures the emulsion of engine oil and condensation water in the oil return pipe of the turbocharger and in the crankcase vent can also freeze. This leads to disturbed engine compression ratios.

Biodiesel presents a high risk for engine oil and turbocharger. Vegetable oils do not evaporate, and unburnt vegetable oils collect in the engine oil. This becomes viscous and the lubrication system collapses soon afterwards. Therefore, much shorter intervals between oil changes are necessary if vegetable oils are used as a fuel.

And finally, a few tips for turbo customers:

- Let the engine run at idling speed for around 30 seconds before switching off to ensure the supply of oil to the turbocharger, and 30 seconds idling after a fast trip on the motorway cools the turbocharger.

- Drivers whose journeys are mainly short trips should take a longer trip at least once a week to give the engine oil the chance to regenerate .

- To help get the engine up to working temperature faster in winter, wait for three minutes before switching the heater on and it will then heat up quicker too.