When your vehicle’s computer encounters an issue, it will send out a code. These codes have an established formula and can be read using an OBD port scan tool connected to the car’s OBD port.

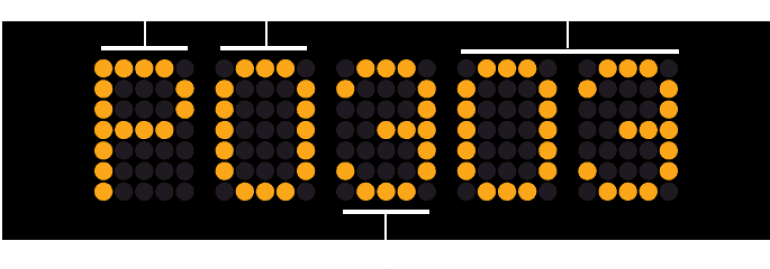

An OBD2 code typically consists of a letter prefix followed by four numbers. The initial number determines whether the code is generic (SAE) or manufacturer-specific.

PIDs

PIDs are an integral component of the OBD II code process and can be utilized for various tasks, such as clearing diagnostic trouble codes or monitoring engine performance. Furthermore, they help identify the source of an error and pinpoint its underlying cause.

PIDs work by creating a constant variation of output within an adaptive control loop feedback mechanism to precisely regulate a process. This helps eliminate oscillation and provide accuracy and stability within the system.

The three components of the PID control equation are Proportional Gain, Integral, and Derivative. All three must be tuned appropriately for your application; there are various methods available for doing this.

A proportional value will have a large immediate effect on the output, as it’s calculated each time the controller performs PID calculations (typically every 100 milliseconds). On the other hand, an integral value has less of an immediate effect than its proportional counterpart, since it accumulates over time rather than being calculated immediately after being set. Therefore, an integral can exert more influence over output over longer time intervals than its proportional counterpart does.

PIDs are a popular choice among many in the automotive industry, as they can be an invaluable aid in pinpointing an error. Not only are PIDs straightforward to comprehend and verify with various electrical, temperature, vacuum or pressure tests, but they are also easy to implement.

For instance, engine coolant temperatures can be verified using either a noncontact temperature tester or digital visual oscilloscope (DVOM), and intake manifold vacuum verified using a vacuum gauge. If either test fails, then the issue could lie with either sensor or circuitry.

Another method for reading PIDs is using a scan tool, which can also help pinpoint the source of an error. These programs display PID data from a vehicle and pinpoint which sensor or component has issues.

Pending

Pending codes are an intriguing type of diagnostic trouble code, and they can be helpful when trying to diagnose what the issue is. Unfortunately, they are not always indicative of a major problem.

When your car’s OBD II system detects a problem, it will store the details as a diagnostic trouble code. These codes are universal across all OBD II vehicles and provide helpful insight into what may be wrong with your vehicle.

These codes can range in complexity from easy to complex, but the important thing is that they help you figure out what’s wrong with your vehicle. Once you understand what the code indicates, you can make an informed decision as to how best to address the problem.

Codes come in many forms, but the most widespread are standard or generic ones used on any OBDII-compatible vehicle. These codes typically indicate issues with engine and emissions equipment such as a misfire, an evap leak or malfunctioning oxygen sensor.

Some codes are more critical, meaning that if not resolved quickly, they can cause an immediate and serious issue. For instance, if an oxygen sensor malfunctions leading to emission control issues, this would be considered a critical matter that must be addressed promptly.

The second type of code is known as a “non-critical,” which pertains to things like window washer fluid levels or cabin air filters. Since these errors are less urgent, they may be easier to address.

Though these codes typically don’t activate the check engine light, they should still be taken seriously since they could indicate an underlying issue that needs to be addressed before getting worse.

One major distinction between a stored code and a pending code is that a pending code has occurred multiple times but hasn’t yet been confirmed as an ongoing problem by the ECU (engine control unit). For the ECU to recognize there’s an issue worth fixing, it needs confirmation in multiple driving cycles.

Active

An active code is an error that has caused your Check Engine light to illuminate. These codes are vital and should be checked regularly in order to avoid major problems with your vehicle.

Pending codes are similar to active codes in that they indicate errors that haven’t yet triggered your Check Engine light. They’re stored in the ECU’s memory and will be upgraded back into an active code if they happen again.

In most cases, an OBD scanner will be able to view both active and pending OBD codes separately. This is because the scanner communicates with your vehicle’s OBD port to gather all relevant information necessary to diagnose what’s causing the current issue.

A scanner can also erase or reset any pending codes on your vehicle, allowing the tool to diagnose all potential problems with ease.

There are four sets of codes commonly used: P for powertrain, B for body, C for chassis and U for network systems. Each set has a distinct character which indicates where in the vehicle the issue occurred.

The initial character indicates whether a code is generic or manufacturer specific. Generic codes cover issues that affect all cars, while manufacturer specific codes pertain only to parts made for a certain model or make.

Generally, it’s safe to assume the codes you receive with your scanner are generic since most manufacturers use the same list of codes for communication with their vehicles. However, if you have any doubts about any of the codes received, consult a mechanic.

You can also use an OBD code interpretation website to learn what each letter and digit mean when seen on your code. Doing this will enable you to identify the specifics of your issue and how best to resolve it.

OBD-II utilizes two main standards – J1939 and the Emissions Control Standard (ECS). The former was created by the Society of Automotive Engineers to help vehicles comply with emission laws. It also contains a common list of diagnostic trouble codes (DTCs) used across all manufacturers. While these universal codes are widely utilized, manufacturers may still create their own DTCs if their system requires them.

Cleared

Cleared codes are a common issue, but can be challenging to locate without an OBD II diagnostic tool. National Field Trainer Jason Gabrenas shares this Quick Tip on how to detect them using the OBD II mode 10 feature of a scan tool.

All vehicles contain either “pending” or “stored” codes that do not activate the check engine light until they are detected a certain number of times. Therefore, these may not be true fault codes and don’t need to be fixed right away.

However, codes can serve as a warning sign of another problem within the vehicle that has yet to be addressed. For instance, a code could suggest that your fuel control system is malfunctioning.

The fuel control system is part of the Engine Control Module (ECM), and contains sensors that monitor various conditions within a vehicle. When they detect an issue, they’ll send a code to the PCM so it knows what action should be taken.

As a result, the PCM will generate a DTC or Diagnostic Trouble Code for that specific failure. These DTCs help diagnose the root cause of malfunction and are mandated by law on all OBD II systems.

Each code is typically five digits long and begins with the letter p. It may end in four numbers or may substitute a letter for one of the numbers in the code.

For instance, if the code is P0420, it indicates that the ECM is detecting an issue with the fuel control system. This could be caused by either a leak in the system or other issues affecting performance of this component.

No matter the issue, make sure it’s a genuine problem with the vehicle. If so, take it to a mechanic for an extensive diagnosis.

Thankfully, there are a variety of tools to assist with this task. Some are simple wired scanners while others may be more professional-grade and manufacturer-specific. Although these may be costly investments, if used properly they can prove worth the expense.