OBD2 can make the impossible diagnosis possible, find the hidden malfunction that might otherwise be overlooked, and prevent comebacks. You don’t even have to buy it – it is built into every 1996 or later car and light truck, foreign or domestic, sold in the United States (1998 and later in Canada). There is much more to OBD2 than diagnostic trouble codes. Conceived to isolate malfunctions capable of increasing emissions by 50% or more above federal or California standards, OBD2 has matured into a comprehensive diagnostic system. To access its remarkable capabilities, all you need is a Scan Tool.

OBD2 can make the impossible diagnosis possible, find the hidden malfunction that might otherwise be overlooked, and prevent comebacks. You don’t even have to buy it – it is built into every 1996 or later car and light truck, foreign or domestic, sold in the United States (1998 and later in Canada). There is much more to OBD2 than diagnostic trouble codes. Conceived to isolate malfunctions capable of increasing emissions by 50% or more above federal or California standards, OBD2 has matured into a comprehensive diagnostic system. To access its remarkable capabilities, all you need is a Scan Tool.

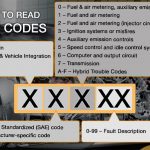

Codes and Monitors

Checking the status of Monitors is as important as checking for Diagnostic Trouble Codes (DTCs). A “Monitor” – the process and standards by which the Powertrain Control Module (PCM) tests an emissions-related system – is what sets a DTC. But, Monitors cannot set a code if they do not first run through the testing that would discover a malfunction. “Continuous” Monitors (i.e., Comprehensive Component Monitor (CCM), Fuel System Monitor, and Misfire Monitor) run whenever the engine is operating. But, “Non-continuous” Monitors run only when specific “enabling criteria” are met, and some of them cannot run until another Monitor completes. Even when a Monitor shows “ready,” indicating that it has run and completed, it may not have run recently.

This means OBD2 can be a valuable diagnostic tool even when no trouble code is stored and the Malfunction Indicator Light (MIL) on the instrument panel is not illuminated. Instead of guessing, you can simply do a little driving and let OBD2 complete a “drive cycle,” sometimes called a “trip.”

A drive cycle is the driving pattern that satisfies “enabling criteria” for a Monitor; the conditions which must pre-exist for the Monitor to run. A full drive cycle meeting the enabling criteria for all Monitors – termed a “global” drive cycle or trip – may be time consuming, requiring as much as a half-hour to accomplish. But, the drive cycle that enables a specific Monitor may require only a few minutes. (The drive cycle for each Monitor is unique to that Monitor, and drive cycles differ among vehicle manufacturers.)

Employing drive cycles is an effective way to focus diagnosis. OBD2 DTCs are very specific, designed not only to pinpoint the system setting the code, but also the malfunction within that system. For example, OBD2 does not merely set an oxygen sensor code. OBD2 codes distinguish between high voltage, low voltage, slow transition time, and insufficient transition. Performing a drive cycle uses the OBD2 system to obtain the freshest and most specific diagnostic data the system can generate. Once the drive cycle has been concluded, connecting the Scan Tool should tell you whether the Monitor completed and whether is a code set, either active or “pending.”

If there is no code, it suggests that there is no malfunction in the monitored system. However, a pending DTC can be stored without illuminating the MIL. Non-continuous Monitors may illuminate the MIL only if the malfunction is detected during two consecutive drive cycles, storing the code when first detected only as a pending code. Retrieving codes with a Scan Tool after concluding a drive cycle is essential to verify that a Monitor did complete and that no code is active or pending. (Be sure to shut the engine off to conclude the drive cycle.)

Freeze Frame Data

OBD2 captures “Freeze Frame” data at the moment a DTC is set, data which is easily retrieved with a Scan Tool. The data includes whether the engine was in open or closed loop, engine rpm, coolant temperature, vehicle speed, calculated engine load, short term and long term fuel trim for each bank, and intake manifold absolute pressure.

Freeze Frame data provides the operating context for a trouble code. Knowing what the engine and vehicle were doing when the code set may provide clues to its cause. Anomalies in Freeze Frame data can help pinpoint specific systems as suspect. Freeze Frame data within manufacturer’s specifications allows you to exclude specific systems, at least provisionally, further narrowing your diagnostic focus.

When more than one code has been set, the Freeze Frame displays data for the code with highest “priority.” Misfire codes have priority over all other codes. Codes which illuminate the MIL when they first occur have priority over those that do so only after a second consecutive drive cycle. Non-emissions related codes are the lowest priority. Though Freeze Frame will overwrite data stored for a previous code of lower priority, other codes should be considered as an element of Freeze Frame data. The conditions setting the lower priority code may have existed when the Freeze Frame code was set and may be contributing to the underlying malfunction.

Enhanced Diagnostic Trouble Codes

There is yet another way that OBD2 can help you diagnose a vehicle malfunction: manufacturer-specific “enhanced” Diagnostic Trouble Codes.

Unlike the definitions of generic OBD2 codes, which are common among all vehicle manufacturers, the definitions of enhanced codes are determined by the specific manufacturer. Though enhanced codes share the same numbering system – P1XXX, distinguishing them from the P0XXX format of generic OBD2 codes – the definitions are applicable only to vehicles of the specific manufacturer defining that particular code. Vehicle manufacturers use enhanced codes to provide additional diagnostic data about systems already monitored by OBD2. The recent addition of new code number sequences to accommodate future expansion of the OBD2 system underscores the complimentary importance to OBD2 diagnostics of enhanced codes. The addition of generic code numbers formatted as P2XXX and P3XXX is accompanied by new enhanced code numbers also formatted as P3XXX.

By using the Scan Tool to retrieve any enhanced codes that have been set, you can key into specific diagnostic procedures recommended by the manufacturer that will help pinpoint the underlying malfunction and save time. For example, the generic code for the secondary air injection system is P0410. General Motors has created enhanced codes P1415 and P1416 to localize an AIR problem to specific cylinder banks, codes which apply only to GM vehicles and for which GM has established specific diagnostic trees.

Live Data

Diagnostic Trouble Codes, generic or enhanced, and the Freeze Frame capture are data already stored in the PCM, which you can retrieve with your Scan Tool in a few minutes. This is data that you can use to begin the diagnosis, exclude possible causes, and focus on others.

OBD2, however, can do more. OBD2 can provide “Live Data,” allowing you to use the OBD2 system and your Scan Tool to watch what the powertrain and emissions systems are doing as the engine is running or the vehicle is driven. The Live Data capability allows you to see what is being reported to the PCM, as it is being reported, in real time.

Live Data includes whether the engine is operating in open or closed loop, calculated engine load, coolant temperature, intake air temperature, throttle position, short and long term fuel trim for each bank, intake manifold absolute pressure, engine rpm, vehicle speed, spark advance, and oxygen sensor voltage for each bank. All these Live Data streams can be viewed simultaneously, or you can select only those you wish to view. Live Data also allows you to record this data – triggered either automatically before, during, and after a trouble code is set or manually.

Live Data is the perfect adjunct to your diagnostic expertise and imagination. After writing down all stored codes and Freeze Frame data and using Freeze Frame data as the reference, Live Data allows you to verify during a test drive (with an assistant, of course) that you have duplicated conditions existing when a code was set and record, at your option, Live Data before, during, and after the code resets. Live Data also can help diagnose codes lower in priority than the Freeze Frame code and for which, consequently, there is no Freeze Frame data. Using Live Data, you can test drive the vehicle to duplicate circumstances that would allow that lower priority code to set, then manually trigger data recording.

Live Data is inherently flexible. You can tailor it to look where you want, for what you want to see, simply by operating the engine or vehicle in the conditions you wish to examine. You are not restricted to circumstances that set the code you are investigating, so you can observe and record data in real time during other engine operating conditions that may help make a diagnosis.

For example, if Freeze Frame shows that a lean code set in open loop at low coolant temperature, Live Data allows you to watch fuel trim as the engine warms and goes into closed loop. A vacuum leak setting a lean code would be expected to show approximately 20% total positive fuel trim correction at idle. If fuel trim in Live Data shows no lean condition in closed loop at operating temperature, the cause of the lean code may be a temperature related vacuum leak, such as an intake manifold leak that seals when the manifold expands as it heats. Locate that vacuum leak, again using Live Data. Introduce propane around the manifold gasket and watch the oxygen sensor values. When the oxygen sensor data holds at a high voltage reading, signifying a constant rich condition, the source of the leak has been found.

Repair Verification with OBD2

While OBD2 is an exceptional diagnostic tool, it is not merely a diagnostic tool. OBD2 also allows you to verify repairs. Test the repair by performing a drive cycle that runs the Monitor for the repaired system. Then connect your Scan Tool to check for codes. If the Monitor for the repaired system has set no code, active or pending, then the repair is verified. You can also use Freeze Frame data to verify a repair. Drive the vehicle using Live Data to duplicate the exact conditions captured in the Freeze Frame. If the malfunction does not recur, and Live Data confirms the repaired system is operating properly, the repair is verified.

OBD2 can even prevent comebacks for hidden malfunctions that might otherwise be overlooked. Because some Non-continuous Monitors run only after others have completed, a malfunction in one system may prevent another from setting a code. Repairing the first system makes it possible for this postponed Monitor to run, but the enabling criteria for the more complex Monitors, such as the Evaporative Emissions (EVAP) System Monitor, may not be met until some time after repairs were performed. To assure that nothing has been overlooked, take a test drive that includes the drive cycle for any postponed Monitors or perform a global drive cycle.

So, don’t stop when you’ve retrieved the codes.

Retrieving codes is only the beginning of what OBD2 can do for you.

Hi Alex,

Wondering if OBD analysis can be used in a crash investigation for any usable info? There’s a lot about EDR forensices, but can’t find any mention of OBD.

EDR only stores data for 5 seconds in many instances, however. I’m especially interested if OBD might pick up something related to Sudden Unintended Acceleration?

Thanks