Diagnostic Computer for Cars: A Comprehensive Guide

Modern vehicles are complex machines with intricate systems controlled by computers. When something goes wrong, a diagnostic computer for cars can be an invaluable tool for identifying the issue. This comprehensive guide will explore the world of car diagnostic computers, covering everything from the basics of the OBD-II system to advanced diagnostic techniques and training resources.

What is a Car Diagnostic Computer?

A car diagnostic computer, also known as an OBD-II scanner or code reader, is an electronic device that connects to a vehicle’s onboard diagnostic system (OBD-II) to retrieve information about its performance and potential problems. The OBD-II system monitors various components and reports diagnostic trouble codes (DTCs) when malfunctions occur. These tools have revolutionized how we maintain and repair our vehicles, providing valuable insights into the inner workings of our cars.

The OBD-II System

The OBD-II system, like a vehicle’s health check mechanism, constantly monitors different parts and systems. When it detects a potential problem, a warning light, often called the “Check Engine” light, illuminates on the dashboard. The OBD-II system was mandated in the United States starting with 1996 light-duty vehicles. While its primary function is to monitor emissions and ensure compliance with environmental regulations it also plays a crucial role in overall vehicle diagnostics.

History of OBD Systems

The concept of onboard diagnostics dates back to the 1960s, with pioneers like Volkswagen introducing early forms of computerized diagnostics. However, it wasn’t until the late 1980s that the Society of Automotive Engineers (SAE) recommended standardization. This led to the development of OBD-I, which was the first generation of onboard diagnostic systems. OBD-I systems were primarily focused on emissions control but lacked standardization across different vehicle manufacturers.

In 1996, OBD-II was introduced as a standardized system in the United States for all vehicles. OBD-II provided a universal connector and a set of standardized diagnostic trouble codes (DTCs), making it easier for technicians to diagnose and repair vehicles from different manufacturers. This standardization also paved the way for the development of more advanced diagnostic tools and software.

Components of the OBD-II System

The OBD-II system consists of several key components:

- Electronic Control Unit (ECU): The ECU is the brain of the car, responsible for monitoring and controlling various systems. It receives data from sensors throughout the vehicle and uses this information to regulate engine performance, emissions, and other functions.

- Sensors: Sensors are located throughout the vehicle, monitoring various parameters such as engine temperature, oxygen levels, and vehicle speed. They collect data and send it to the ECU for analysis.

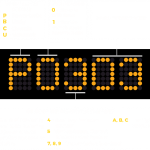

- Diagnostic Trouble Codes (DTCs): When a sensor detects a problem, the ECU generates a DTC, which is a code that identifies the specific issue. These codes can be read using an OBD-II scanner.

- OBD-II Port: The OBD-II port is a standardized 16-pin connector located under the dashboard, typically on the driver’s side. It provides access to the vehicle’s diagnostic system.

- Malfunction Indicator Light (MIL): The MIL, commonly known as the “Check Engine” light, is a warning light on the vehicle’s dashboard that illuminates when the ECU detects a malfunction. It serves as an early warning system for vehicle problems.

OBD-II and Emissions Testing

OBD-II systems play a crucial role in emissions testing. In California, for example, technicians are required to perform an OBD-II check during Smog Check inspections. The technician visually checks to ensure the MIL is functional, and then the Smog Check test equipment communicates with the onboard computer to retrieve fault information. This helps ensure that vehicles meet emissions standards and contribute to cleaner air quality.

Functions of a Car Diagnostic Computer

A car diagnostic computer can perform various functions, providing valuable information for both DIYers and professional mechanics.

- Reading and Clearing Codes: The primary function is to read and clear DTCs. This allows you to identify the source of the “Check Engine” light and other warning lights. For example, a code reader can help diagnose and reset a check engine light triggered by a faulty sensor.

- Monitoring Sensor Data: Many diagnostic computers can monitor real-time data from various sensors, such as engine RPM, vehicle speed, and coolant temperature. This helps diagnose issues that don’t always trigger a code. By observing live data, you can gain insights into the performance of various systems and identify potential problems before they escalate.

- Performing Active Tests: Some advanced diagnostic computers can perform active tests, also known as bidirectional controls, where you can send commands to the vehicle’s systems and components to test their functionality. This allows you to directly test components like solenoids, actuators, and relays to pinpoint the source of a problem.

- Retrieving Freeze Frame Data: Freeze frame data captures a snapshot of the vehicle’s sensor readings at the moment a DTC was triggered. This can be helpful in diagnosing intermittent problems. By analyzing the freeze frame data, you can gain a better understanding of the conditions that led to the fault.

- Viewing Live Data Streams: Some diagnostic computers can display live data streams from multiple sensors simultaneously, allowing you to observe how different systems interact. This can be particularly helpful in diagnosing complex issues that involve interactions between multiple systems.

- Checking Emissions Readiness: Diagnostic computers can check if your vehicle’s emission control systems have completed their self-tests and are ready for an emissions test. This helps ensure that your vehicle meets emissions standards and avoids failing an emissions test.

Understanding the different functions of a car diagnostic computer can help you choose the right tool for your needs and use it effectively to diagnose and repair your vehicle.

How to Use a Car Diagnostic Computer

Using a car diagnostic computer is generally a straightforward process, but it’s important to follow the correct steps to ensure accurate results.

- Locate the OBD-II port: The OBD-II port is typically located under the dashboard on the driver’s side. It may be hidden behind a cover or panel, so consult your vehicle’s owner’s manual if you have trouble finding it.

- Plug in the scanner: Connect the diagnostic computer to the OBD-II port. Ensure the connector is properly seated to establish a good connection.

- Turn on the ignition: Turn the ignition key to the “on” position without starting the engine. This powers up the vehicle’s computer system and allows the scanner to communicate with it.

- Follow the scanner’s instructions: The scanner may prompt you to enter vehicle information, such as the year, make, and model, or select specific functions. Follow the on-screen prompts to ensure the scanner is properly configured for your vehicle.

- Read the codes: Retrieve the DTCs from the vehicle’s computer. The scanner will display the codes, which are typically a combination of letters and numbers.

- Interpret the codes: Use the scanner’s built-in library or an online database to understand the meaning of the codes. Some scanners provide a brief description of the issue, while others may require you to look up the codes online or in a service manual.

- Clear the codes (if applicable): After fixing the issue, clear the codes using the scanner. This resets the check engine light and removes the codes from the vehicle’s memory. However, it’s important to only clear codes after you’ve addressed the underlying problem.

By following these steps, you can use a car diagnostic computer to effectively diagnose and repair your vehicle.

Types of Diagnostic Tools for Cars

A variety of diagnostic tools are available to help identify and resolve vehicle problems.

1. OBD-II Scanners

OBD-II scanners are the most common type of diagnostic tool. They range from basic code readers to advanced scan tools with comprehensive diagnostic capabilities.

- Code Readers: Code readers are basic devices that can read and clear codes from any OBD-II equipped vehicle. They are typically more affordable than scan tools but offer limited functionality.

- Scan Tools: Scan tools are more advanced devices that offer a wider range of functions, such as viewing live data streams, performing component tests, and accessing manufacturer-specific codes. They are essential for professional mechanics and serious DIYers.

2. Other Diagnostic Tools

In addition to OBD-II scanners, several other tools are commonly used in vehicle diagnostics:

- Multimeter: A multimeter is a versatile tool that measures voltage, current, and resistance in electrical circuits. It is essential for troubleshooting electrical problems in a vehicle.

- Compression Tester: A compression tester measures the compression pressure inside each cylinder of the engine. This helps diagnose engine-related issues such as worn piston rings or leaking valves.

- Smoke Machine: A smoke machine is used to diagnose vacuum leaks in the intake or exhaust system. It introduces smoke into the system to reveal leaks.

These tools, along with OBD-II scanners, provide a comprehensive toolkit for diagnosing and repairing modern vehicles.

Types of Diagnostic Computers for Cars

Diagnostic computers for cars come in various forms, each with its own set of features and capabilities.

1. Handheld Scanners

Handheld scanners are portable devices with a built-in display and buttons for navigation. They are popular among DIYers and mechanics for their ease of use and affordability. Some popular handheld scanners include the Innova 6100P, which offers a color display, live data, and the ability to reset battery test and oil lights, and the Ancel BD310, which provides both corded and Bluetooth connectivity.

2. Laptop-Based Systems

Laptop-based systems use a laptop or PC with diagnostic software to access and analyze vehicle data. They offer more advanced features and capabilities compared to handheld scanners, such as data logging, graphing, and advanced diagnostics. Some popular laptop-based systems include OBDwiz, which is compatible with all PC-based scan tools sold on ScanTool.net, and Torque Pro, which is easy to use on Android and Windows and offers real-time data monitoring and customizable dashboards. To connect a car diagnostic computer to a laptop, you typically need an OBD-II to USB cable or a Bluetooth adapter. The specific steps for connecting may vary depending on the diagnostic software and adapter being used.

3. Mobile Device-Based Tools

Mobile device-based tools use a smartphone or tablet with diagnostic software and a Bluetooth adapter to connect to the vehicle’s OBD-II port. They offer portability and convenience, allowing users to access diagnostic information on their mobile devices. Some popular mobile device-based tools include OBD Fusion, which is available for iOS and Android and offers enhanced diagnostics, and Car Scanner ELM OBD2, which provides a wide range of features for free, including customizable dashboards and live data.

Types of Diagnostic Software for Cars

Diagnostic software plays a crucial role in accessing and interpreting data from a car’s diagnostic computer. There are two main types of diagnostic software:

1. Free Diagnostic Software

Free diagnostic software offers basic functionality, such as reading and clearing codes, viewing live data, and checking emissions readiness. Some popular free diagnostic software options include OBDwiz, which is included with every ScanTool.net PC-based scan tool, and Car Scanner ELM OBD2, which is available for Android and offers a wide range of features for free. EasyObdII is another free software option with features like a user-friendly interface, PDF reporting, and support for various USB and Bluetooth devices.

2. Paid Diagnostic Software

Paid diagnostic software offers more advanced features and capabilities compared to free software, such as manufacturer-specific diagnostics, bidirectional controls, and advanced data analysis. Some popular paid diagnostic software options include TouchScan, which offers add-ons for specific car manufacturers, and OBD Auto Doctor, which provides features like real-time data monitoring, service routine initiation, and customizable dashboards. AutoEnginuity is another paid option with bundles for Asian, Domestic, and European vehicles. Snap-on also offers a range of diagnostic software with features like SureTrack Top Repairs and Fast-Track on-tool content.

Types of Diagnostic Cables for Cars

Diagnostic cables are used to connect the diagnostic computer to the vehicle’s OBD-II port. There are two main types of diagnostic cables:

1. Generic Diagnostic Cables

Generic diagnostic cables are designed to work with a wide range of vehicles and diagnostic computers. They typically have a standard OBD-II connector on one end and a USB, Bluetooth, or Wi-Fi connector on the other end. These cables are widely available and offer a cost-effective solution for basic diagnostics. Examples include OBD-II extension cables, splitter cables, and OBD-II to USB cables.

2. Manufacturer-Specific Diagnostic Cables

Manufacturer-specific diagnostic cables are designed to work with specific car makes or models. They may have a different connector on one end to connect to a proprietary diagnostic port on the vehicle. These cables are often used with manufacturer-specific diagnostic software to access advanced functions and data. For example, there are manufacturer-specific cables for brands like Volvo, Iveco, and Mercedes-Benz.

Types of Diagnostic Connectors for Cars

While the OBD-II connector is the most common type of diagnostic connector in modern cars, there are other types of connectors that may be found in older vehicles or specific car makes.

1. OBD-II Connector

The OBD-II connector is a standardized 16-pin connector found in most cars built after 1996. It provides a universal interface for accessing diagnostic information. OBD-II connectors come in two types: Type A for cars (12V) and Type B for medium/heavy vehicles (24V). The difference lies in their baud rates, with Type A having a higher baud rate of approximately 500,000 bauds compared to Type B’s maximum baud rate of 250,000 bauds.

2. Manufacturer-Specific Connectors

Some car manufacturers use proprietary diagnostic connectors in addition to or instead of the OBD-II connector. These connectors may have a different number of pins or a different shape. For example, some older BMWs have a 20-pin connector. These connectors are often used for accessing manufacturer-specific data and functions that are not available through the standard OBD-II connector.

3. Pre-OBD-II Connectors

Vehicles manufactured before the widespread adoption of OBD-II may have different types of diagnostic connectors. These connectors vary significantly between manufacturers and may require specialized adapters or cables to connect to a diagnostic computer.

Types of Diagnostic Codes for Cars

Diagnostic trouble codes (DTCs) are used to identify specific malfunctions in a vehicle. There are two main types of diagnostic codes:

1. Generic Diagnostic Codes

Generic diagnostic codes, also known as standardized codes, are common to all OBD-II compliant vehicles. They are defined by the Society of Automotive Engineers (SAE). These codes provide a universal language for identifying common vehicle problems, making it easier for technicians to diagnose and repair vehicles from different manufacturers.

2. Manufacturer-Specific Diagnostic Codes

Manufacturer-specific diagnostic codes are unique to a particular car make or model. They are used to identify issues that are not covered by generic codes. These codes provide more detailed information about specific problems related to the vehicle’s make and model.

Critical vs. Non-Critical DTCs

DTCs can also be categorized as critical or non-critical. Critical DTCs indicate serious issues that can immediately affect vehicle performance and require urgent attention. Non-critical DTCs, on the other hand, may relate to less urgent issues that do not require immediate attention.

Understanding OBD-II Code Structure

OBD-II codes have a specific structure that provides valuable information about the fault.

| Code Type | Description | Example |

|---|---|---|

| P | Powertrain | P0300 (Random/Multiple Cylinder Misfire Detected) |

| B | Body | B0020 (Front Passenger Side Deployment Loop Resistance High) |

| C | Chassis | C0035 (Left Rear Wheel Speed Sensor Circuit) |

| U | Network | U0073 (Control Module Communication Bus A Off) |

Understanding the structure of OBD-II codes can help you quickly identify the system and type of fault, making diagnostics more efficient.

Types of Diagnostic Data for Cars

Diagnostic data provides valuable insights into a vehicle’s performance and health. There are various types of diagnostic data that can be accessed using a car diagnostic computer:

1. Sensor Data

Sensor data includes real-time readings from various sensors throughout the vehicle, such as engine speed, coolant temperature, and oxygen sensor readings. This data can be used to monitor engine performance, diagnose problems, and identify potential issues before they become major. For example, monitoring engine oil temperature can be crucial for those who drive aggressively, as high oil temperatures can lead to oil degradation and engine damage.

2. Actuator Data

Actuator data provides information about the operation of various actuators in the vehicle, such as throttle position, fuel injector pulse width, and brake pressure. This data can be used to diagnose problems with the vehicle’s control systems and ensure that actuators are functioning correctly. For example, monitoring throttle response data can help identify issues with the throttle system, such as delayed or inconsistent responses.

3. Freeze Frame Data

Freeze frame data captures a snapshot of the vehicle’s sensor readings at the moment a DTC was triggered. This data provides valuable context for understanding the conditions that led to the fault and can be helpful in diagnosing intermittent problems.

Types of Diagnostic Reports for Cars

Diagnostic reports provide a summary of the diagnostic data and findings. There are two main types of diagnostic reports:

1. Generic Diagnostic Reports

Generic diagnostic reports provide a general overview of the vehicle’s health and any detected issues. They typically include a list of DTCs, freeze frame data, and live sensor data. These reports are often generated by basic code readers or scan tools and provide a starting point for diagnosing vehicle problems.

2. Manufacturer-Specific Diagnostic Reports

Manufacturer-specific diagnostic reports provide more detailed information about the vehicle’s systems and components. They may include proprietary diagnostic data, technical service bulletins (TSBs), and repair information specific to the car make and model. These reports are often generated by more advanced scan tools or diagnostic software and provide a deeper level of insight into the vehicle’s condition.

History of OBD Interfaces

The evolution of OBD interfaces has played a significant role in the development of car diagnostic computers.

1. ALDL

ALDL (Assembly Line Diagnostic Link) was an early interface used by General Motors (GM) starting in 1981. It was a predecessor to OBD-I and came in different varieties with varying pin-outs and baud rates.

2. OBD-I

OBD-I was the first generation of onboard diagnostic systems, introduced in the late 1980s. It aimed to encourage manufacturers to design reliable emission control systems. However, it lacked standardization, with each manufacturer using its own DLC, location, DTC definitions, and procedures.

What a Car Diagnostic Test Covers

A car diagnostic test can cover a wide range of systems and components, providing a comprehensive assessment of the vehicle’s health.

1. Engine and Transmission

The diagnostic test analyzes the engine and transmission for issues such as misfires, fuel system problems, and transmission malfunctions. It can also monitor sensor data like engine speed, coolant temperature, and throttle position to assess engine performance.

2. Brakes and Exhaust System

The test evaluates the brake responsiveness and exhaust system for problems such as faulty sensors, leaks, and emissions-related issues.

3. Other Systems

The diagnostic test can also assess other systems, including the fuel injectors, ignition coils, throttle, and various sensors. It can also check the vehicle’s onboard computer system for manufacturer notifications or stored information.

Types of Diagnostic Training for Cars

Diagnostic training is essential for anyone who wants to use car diagnostic computers effectively. There are various types of diagnostic training available:

1. Online Courses

Online courses provide a convenient and flexible way to learn about car diagnostics. They cover topics such as OBD-II systems, diagnostic techniques, and troubleshooting. Some online courses offer individualized learning with practicing specialists, access to video recordings, and a practical focus on real-world examples.

2. In-Person Classes

In-person classes offer hands-on training and the opportunity to learn from experienced instructors. They often include practical exercises and real-world scenarios. Some in-person classes provide access to state-of-the-art equipment and resources, such as diagnostic tools, simulators, and electronic automotive information systems.

3. Automotive Diagnostic Training

Automotive Diagnostic Training, with a history dating back to 1971, is a respected provider of diagnostic and emissions training in Southern California. Their mission is to provide training for professional automotive technicians interested in upgrading their skills.

Conclusion

Diagnostic computers for cars are essential tools for identifying and resolving vehicle problems. By understanding the different types of diagnostic computers, software, cables, connectors, codes, data, reports, tools, and training available, you can effectively diagnose and repair modern vehicles. Regular use of a car diagnostic computer can help ensure your vehicle’s optimal performance, safety, and longevity. As vehicle technology continues to advance, staying informed about the latest diagnostic techniques and tools will be crucial for both DIYers and professional mechanics.

For more information on car diagnostic tools, visit Total Car Diagnostics.

Consider investing in a quality car diagnostic computer for accurate and efficient vehicle maintenance.