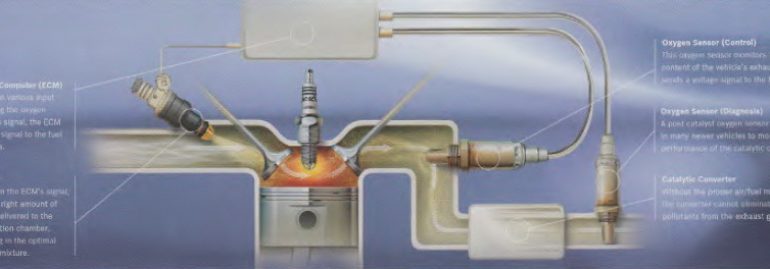

The oxygen sensor is the crucial component and feedback mechanism in the engine management system. It measures the amount of oxygen in the engine’s exhaust gas.

In combination with the catalytic converter, the oxygen sensor controls the exhaust treatment.

It also works with the engine control unit (ECU) to ensure optimal air-fuel mixture composition to deliver smooth, powerful, clean and economical engine performance.

A catalytic converter will only function correctly if the air-fuel mixture composition is correct as it is dependent on the amount of oxygen present in the exhaust.

Properly functioning sensors help reduce fuel consumption, expensive catalytic converter failures and exhaust emissions, and improve performance.

There are two main types of oxygen sensors, ‘switching’ and ‘wideband’.

A ‘switching’ sensor allows the ECU to determine if the exhaust is rich or lean and can be used in both pre-catalyst and post-catalyst positions.

A ‘wideband’ sensor allows the ECU to determine how rich or how lean the mixture is and is used only in the pre catalyst position.

The signal from the pre-catalyst oxygen sensor is primarily responsible for air-fuel mixture adjustments, while the post-catalyst oxygen sensor signal monitors the performance of the catalytic converter and the amount of oxygen being absorbed during its operation.

Oxygen sensors are available as simple single and unheated, two-wire unheated, three and four-wire heated switching sensors and now five-wire wide band sensors.

Heated sensors allow the sensor to reach operating temperatures more quickly, providing a quicker response and more accurate data to the ECU, leading to

lower emissions. Heated sensors also have an extended service life due to lower sensor deterioration from heat stress.

While there are many factors that contribute to premature oxygen sensor failure, it is important to understand that an oxygen sensor is a wear part with a specific service life not unlike a platinum spark plug. An oxygen sensor should have a service life ranging from 50,000 km to 160,000 km depending on its design but this can be dramatically reduced by abnormal operating conditions, including overheating of the sensor, chemical contamination and impact damage.

Over time, and as the oxygen sensor deteriorates, the output from the sensor slows down giving the impression the engine is running lean with the fuel management system overcompensating, thus leading to increases in fuel consumption. It is good practice to check oxygen sensor function at every vehicle major service.

Bosch oxygen sensors are supplied with special high temperature resistant grease for ease of installation. Oxygen sensors should be first tightened by hand until

the sealing washer is in contact with the exhaust mounting boss before using an appropriate spanner tightened to 40-60 Nm.

More precautions:

- Wideband sensors must not be disconnected while operating as this can lead to premature sensor failure.

- The sensor heater supply must never be connected directly to battery supply. The sensors require ECU control of the heater power to avoid thermal-shock, especially if condensation may be present.

- Do not expose hot sensors to water as thermal shock can damage the sensor.

- Do not drop sensors during installation as cracks in the sensor element can occur.

- Do not use any lubricants or sealants that contain silicone.

- Cleaning agents, grease and repellents must not be used on or near the connecting plug.

- The sensor must not be exposed to vehicle under body sealants, wax, tar or rust prevention products. Cover sensor if undertaking body repairs.

- Ensure the sensor cable has free movement to allow for movement in the exhaust system.

I have a 2016 BMW Mini Cooper S which has done 16,600 miles. Recently an “Engine Warning Light” came on and it was found that both sensors had become defective, front was stuck on “Rich”, rear was stuck on “Lean”, both showing as intermittent alarms.

As someone with much experience with electronic and computer systems, I found it odd that both should break down at roughly the same time.

Is this common with these devices, is there a probable cause?